Nail Making Machine Manufacturer & Supplier

With Over 20 Years of Production Experience

We are the leading manufacturer of nail making machines, renowned for our unwavering commitment to quality, innovation, and performance. We specialize in creating state-of-the-art nail making machines that cater to a diverse range of industrial needs, ensuring precision and efficiency.

Nail Making Machine Manufacturer

Reliable Nail Making Machine Supplier

As a leading nail making machine supplier in China, we specialize in a select range of nail making equipment designed for excellence. Our offerings include the versatile 1-6 inch Nail Making Machine for various nail sizes, the High-Speed Thread Rolling Machine for the production of strong, threaded nails at remarkable speeds, the Pulley Type Wire Drawing Machine for precise wire thickness control, and the efficient Coil Nail Making Machine for bulk coil nail production. Each machine in our lineup is engineered with industry-leading technology to guarantee durability, precision, and superior performance for nail manufacturing enterprises aiming for optimal productivity and quality.

Types of Nail Making Machine Products

Our versatile nail-making machine can produce nails from 1 to 6 inches long. Ideal for a wide array of applications, this robust machine promises high speed, reliability, and superior nail quality for all your construction needs.

Our High-Speed Thread Rolling Machine delivers precise threading for various materials, ensuring seamless integration into your manufacturing line for optimal productivity.

Designed for smooth and efficient drawing of metal wires. Its robust pulley system ensures consistent quality and diameter control, making it a reliable choice for your wire manufacturing needs.

This machine is your go-to solution for high-volume, consistent threading tasks, ensuring each coil nail is crafted to meet exacting standards.

Our Typical Coil Nail Making Machine is a versatile and reliable solution for high-speed nail production. It rapidly produces coiled nails with consistent quality, ideal for a wide range of construction and carpentry applications.

Our Conical Coil Nail Making Machine specializes in fabricating conical-shaped coiled nails used for pallets and crates, combining precision, speed, and durability in one compact package.

It is designed for the swift production of coil nails with larger caps. It delivers high-quality, robust nails suitable for roofing and siding where strong holding power is essential.

The Jumbo Coil Nail Making Machine stands out for its capacity to produce extra-large coiled nails at impressive speeds, perfect for industrial-scale projects requiring heavy-duty fastening solutions.

Nail Making Machine for Different Industries

We can provide nail making machines for your applications, just send us your product demands and get our best quote.

Construction

Nails are fundamental in building structures, from residential homes to commercial edifices. They're used in framing, roofing, flooring, and finishing, among other construction tasks.

Carpentry and Woodworking

Precision nails are essential in fine woodworking projects, furniture making, and cabinet installation.

Pallet and Crate Manufacturing

Nails are used extensively in assembling shipping containers, pallets, and crates for the logistics industry.

Fencing and Outdoor Structures

Specialized nails are manufactured for outdoor applications, enhanced with weather-resistant materials, they offer superior strength and durability.

Why Choose Us as Nail Making Machine Supplier

Superior Material Handling

We utilize a proprietary wire straightening and cutting mechanism that minimizes material stress, ensuring the structural integrity of every nail produced and extending the life span of the tooling components.

Eco-Friendly Operation

Beyond being energy-efficient, our nail-making machine features a dust and noise reduction system, making it more environmentally friendly and operator-friendly without compromising productivity.

Scalable Automation

Our machine is designed to seamlessly integrate with additional automation modules, such as nail polishing, sorting, and packaging units, giving users the flexibility to scale up their production line as their business grows.

Exceptional After-Sales Support

We provide industry-leading after-sales service, including a comprehensive warranty, access to spare parts, and responsive technical support, ensuring our customers' operations run smoothly at all times.

Nail Types That We Can Make

1-6 Inch Common Wire Nails

1-6 Inch Common Wire Nails

Nail diameter:1.8-6 mm Speed:200-450 pcs/min Power:4 kw

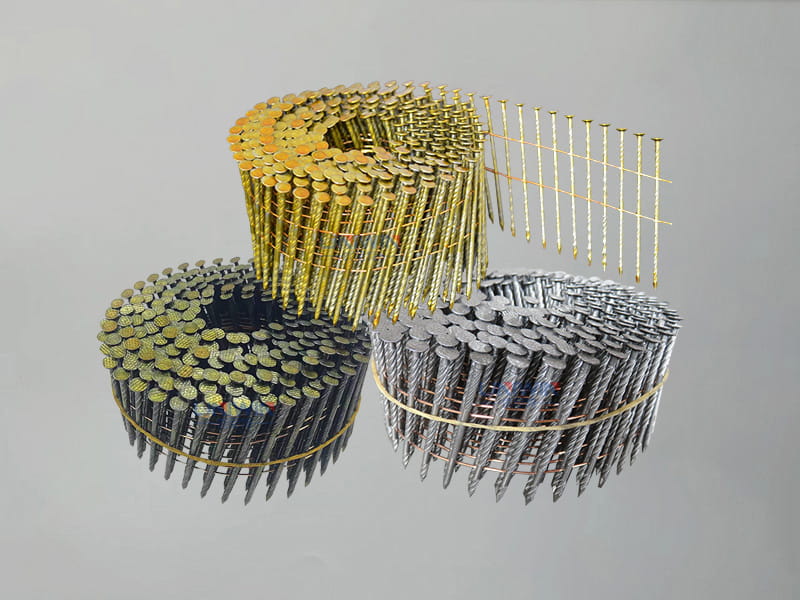

Coil Nails

Coil Nails

Max speed: 3000 pcs/min Working power: 5 kw Dimensions: 2700*900*1200 mm

Umbrella Head Roofing Nails

Umbrella Head Roofing Nails

Max Nail Length: 100mm

Speed: 120 pcs/min

Motor: 4kw

Double Head Nails

Double Head Nails

Diameter of nails: 1.8-5.5 mm Speed: 200 pcs/min

Weight: 2 tons

Clout Nails

Clout Nails

Speed: 220psc/min

Nail Length: 30-100mm

Nail Diameter: 2.5-4.5mm

U Nails

U Nails

Nail Diameter: 2.0-4.5mm

Nail Length: 20-100mm

Production Speed: 240psc/min

Concrete Nails

Concrete Nails

Diameter: 2.0-4.8mm

Speed: 220 pcs/min

Motor: 4 kW

Screw Nails

Screw Nails

Diameter of screws: 1-5 mm

Speed: 170 pcs/min

Motor: 4kw

Nail Making Machine Project Video

Nail Making Machine Factory and WorkShop

What Our Customer Say:

“The reliability and precision of Nail Making Machine’s machines are second to none. We’ve reduced machine downtimes and increased our product quality significantly.”

Jhone Smith

from South Africa

“Exceptional aftersales support and maintenance have made all the difference in keeping our production line smooth and efficient.”

Karl Antony

from Ghana

“Investing in their technology has given us an edge over competitors. The machine’s easy operation and low maintenance have been great for our business.”

Jason Redy

from Morocco

Get a Free Quote

Take action now! Contact us to elevate your manufacturing process and watch your productivity soar!

Blogs About Nail Making Machine

A nail making machine is a mechanical device that creates nails of various sizes and shapes. It typically combines cutting, bending, and welding techniques to form nails from metal rods or wire. The end product can be used for carpentry, construction, and other industrial applications.